- Email: seventcl@163.com

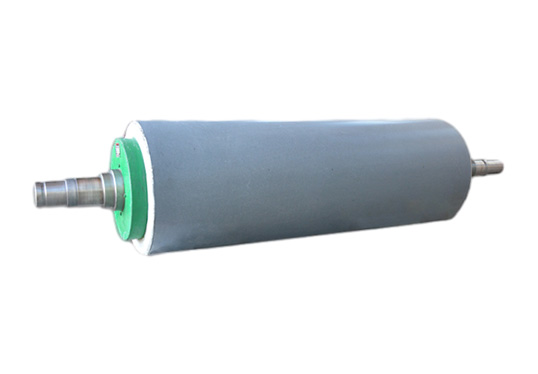

Natural granite press roller is an important part for press dewatering on paper machine. It has the characteristics of smooth surface, high hardness, high strength, acid resistance and alkali resistance.

Granite roller surface is smooth, but there are many tiny micropores and good air permeability. Therefore, wet paper is easy to fall off, which is especially beneficial to paper receiving operation and is widely used in various paper machines.

| Specifications | 300-1500mm in diameter and 1-8m in length. |

| Models | 787, 1092, 2880, 1575, 1600, 1760, 1880, 2100, 2362, 2400, 2640, 3150, 3600, 3800, 4500. |

| Compressive strength | ≥98.07MPa |

| Hardness HV | >300 |

| Tensile strength | ≥5MPa |

| Elastic modulus | ≥0.4X1000000 kg/cm |

It is advisable to store it indoors, so as to avoid cracks on the roller surface caused by temperature changes in the open air, especially in cold regions.

Pay attention to protect the roller surface when loading the car to prevent bumping and scratches.

Granite is a heterogeneous material. When using it, the stress should be balanced to avoid vibration and tension.

When in use,the temperature rise of bearings at both ends shall not exceed 40 degrees, so as to avoid the influence on the use due to the large temperature difference between inside and outside the roller caused by excessive temperature, which may cause cracks on the roller surface or loose mandrel and roller, especially the copper shaft or babbitt alloy shaft.

The line pressure shall not exceed 60KN/M(60Kgt/cm)when used under pressure.

The end face of granite press roller is marked with a rotating arrow, which shall not be reversed during installation.