- Email: seventcl@163.com

Pulp and paper industry

After cooking or mechanical grinding, screening and bleaching, the pulp can not be directly used to make paper.

Because the fibers in the pulp lack of the necessary flexibility, the binding force between the fibers is not ideal. If it is used to make paper, the paper will be loose, porous, rough surface, low strength, can not meet the requirements of use.

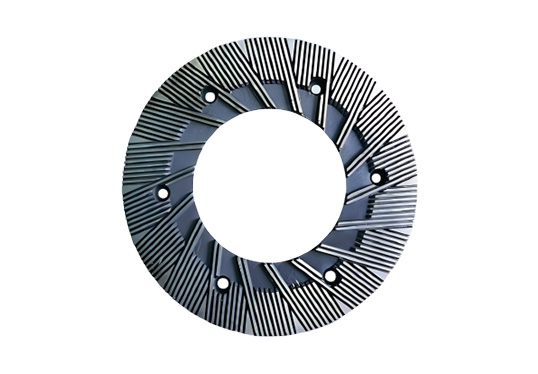

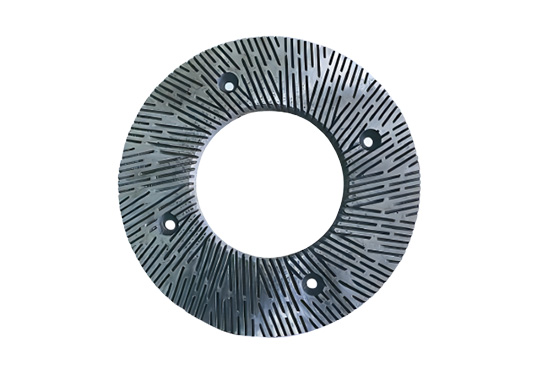

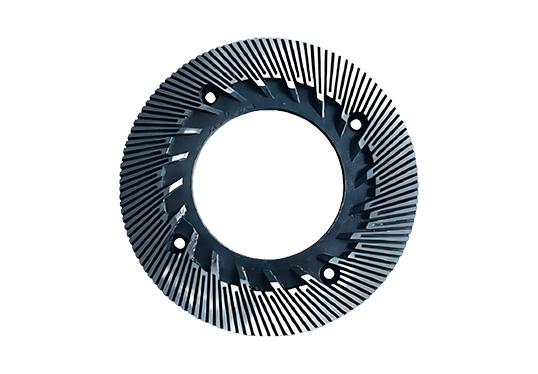

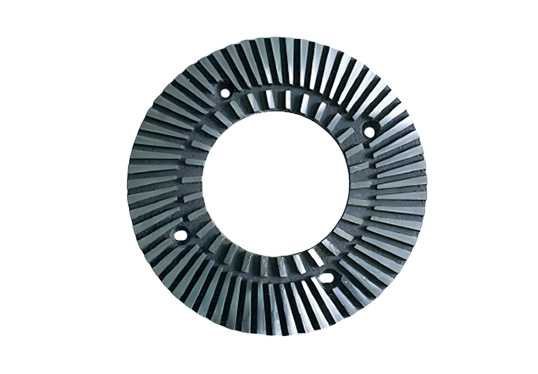

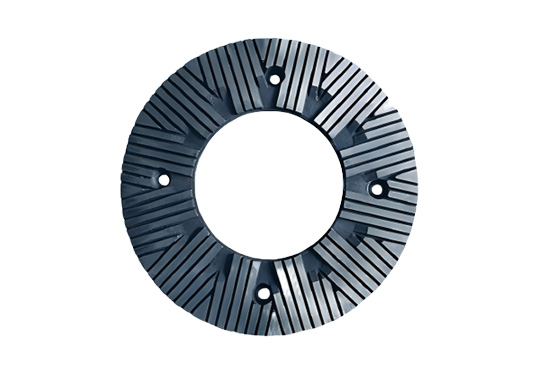

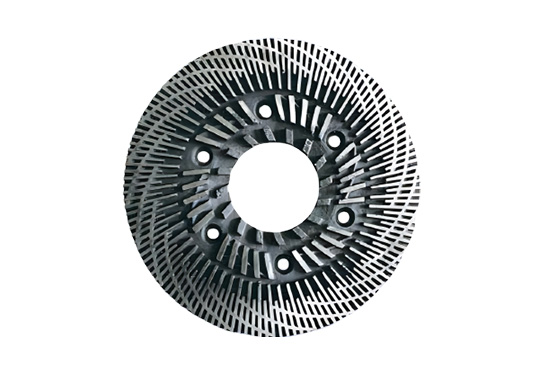

The Refiner Grind Disc is the "heart" of a refiner. There are several to dozens of tooth types for each specification.

Three parts of paper making, seven points beating; beating is to use the mechanical action method of Grind Disc teeth to treat the fibers in the pulp, so that it can be dispersed, moderately cut off and divided into brooms; more importantly, the fiber in beating water swelling, so that it has a higher elasticity and plasticity, to meet the requirements of paper machine production, so that the production of paper can achieve the expected quality indicators.

The theory of specific edge load (SEL) has been followed in the design of grind discs. The research cases of Huayan grinding research center in Nantong and Andritz in Austria show that the specific surface load and rheological effect should be fully considered. The specific edge load theory describes and characterizes the beating characteristics by the effective load per unit length of the impact shear flocculent fiber at the intersection of the rotating tooth and the fixed tooth edge. It is determined by the effective power (net power) n, rotating speed n and the cutting length L of the disc per revolution.

Cone, disc, refiner, dredger, heat dispersion, etc.